Close Control Unit (CCU) also Know as Precision Air Conditioner or Close Control Air Conditioner or Computer Room Air Conditioner (CRAC) or server room air conditioner use for precise control of Temperature and Humidity required for critical application like Server room, Datacenter, Laboratories, Telecommunication room etc.

Modern IT, Telecommunication & laboratory equipments generates a large amount of heat. The problem further increased with higher density IT kit (e.g. Blade Servers).

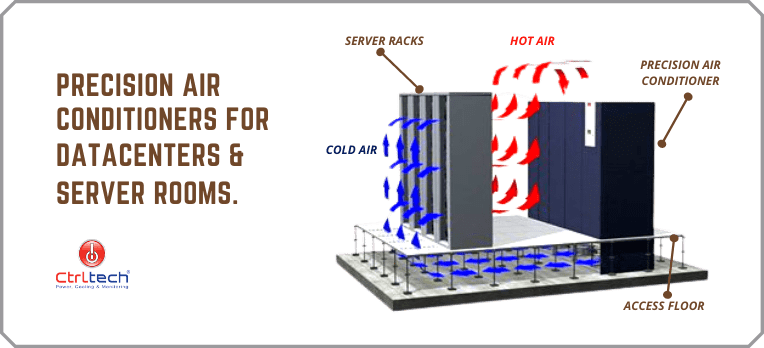

It is, therefore very essential to use the correct type of precision cooling for server room cooling or Datacenter cooling. Also it is very important to understand air flow requirements within server room & Datacenter. Failing to achieve this can have disastrous results with "deadly" hot-spots just where you don't need them - around your key mission critical servers. Hence efficient precision air conditioning for data center cooling (for cooling server and equipments) is critical factor.

In Nutshell Electronic and information procession equipments requires rigid environment conditions with précised control of temperature & humidity for reliable operation. Close control air conditioning systems is specifically designed for concentrated vertical heat loads of today's data centers.

Precision Air Conditioning systems provides efficient heat removal, excellent humidity control, greater airflow, better air filtration, greater flexibility and expandability with numerous alarms and redundancy options. Precision Air conditioner for server room cooling is available in up flow or down flow type based on air throw. Based on coolant and positioning of coil it is broadly classified into Chilled Water (CW) type and Direct Expansion (DX type) type or Dual Fluid (Chilled water + Direct expansion) type. Some of reputed brands are AIREDALE, Liebert, Denco, Uniflair, stulz, Emicon, blue box etc.

There are numerous factors to consider when it comes to perforated ..

SKU: CT-CCU-CRAC-000-DU

MPN: CT-CCU-CRAC-000-DU

Electronic & Information processing equipments requires environment with precise temperature and humidity control with cleanness. Close Control Unit provides not only precise control of temperature and humidity but also air filtration to remove airborne particles which can cause problems.

Most of critical application such as Data center, server room, telecommunication rooms etc requires 24x7 availability of cooling environment with précised control of temperature and humidity. Close Control air conditioning Unit is designed run for 365 days 24x7.

Close Control Unit offers a choice of compressor type. Microprocessor control and other optional features are designed to reduce power consumptions and maximize energy saving. This helps in fast Return of Investment (ROI).

Close Control Unit offer option of down flow and up flow type. Also it can be designed with maximum air flow so that cool air should reach to all corners of datacenter.

CCU is also referred to as a close control air conditioner, a computer room air conditioner, or a server room air conditioner. Close control units regulate not only temperature but also humidity to a precise fixed point. Cooling is the most critical aspect of a data center's operation. The most crucial decision in data centre design is selecting the appropriate cooling system. The reliability of the close control unit is directly tied to the datacenter's uptime. Additional standby units can be installed to increase the cooling system's reliability. As described in our cooling Solutions section, it is critical to move heat created by IT equipment in the datacenter to the outside in order to minimise equipment failure and to extend its life. Datacenter cooling is widely classified into three basic categories based on the medium utilised to convey heat generated inside the datacenter to the outside. There are three types of cooling systems: air cooled systems (DX units), chilled water cooled systems, and dual fluid cooling systems. Along with these categories, there are numerous others such as water-cooled systems and glycol-cooled systems that are rarely employed. Each system type offers a number of distinct advantages and disadvantages.

In many ways, a precision air conditioner is diametrically opposed to a comfort air conditioner. Several significant distinctions include the following:

DX Unit (Direct Expansion) is a type of close control unit that is also referred to as an air cooled system. It makes use of refrigerant to transfer heat generated in the datacenter to the outside. It consists of an indoor unit, an outdoor air-cooled condenser, and refrigerant pipe connecting the two units. Between the internal and exterior condensers, refrigerant circulates to remove heat generated in the datacenter. The heated refrigerant is subsequently cooled at the external condenser. Compression, expansion valve, evaporator coil, heater, blower fan, and filter are all included in indoor units. Compressors can also be installed in outdoor condensing units. The advantage of the DX system is that it is completely self-contained, has a lower overall cost, and is simple to maintain. However, the length of refrigerant piping is limited. We will need to install a glycol-cooled system due to the length of the piping.

As the name implies, this tight control unit technology utilises two distinct mediums to dissipate heat created in the datacenter. It is a mix of a Direct Expansion (DX) unit and a precision air conditioner with chilled water. The system is comprised of a single interior unit that holds the cooling coil, the filter, the humidifier, the heater, and the blower fan. Indoor units are equipped with two cooling circuits: DX and chilled water. Chilled water circuit connected to chilled water supply, which transfers heat via chilled water. While the DX circuit is connected via copper refrigerant piping to the external air-cooled condenser. With the aid of refrigerant, heat is transmitted to the outside. Any one of the cooling circuits may be used as the default, while the others may be used as a standby. Or We can programme the dual fluid server room air conditioner's cooling circuits to operate on a timetable.

Precision air conditioners, often known as CCUs (close control units) or CRACs (computer room air conditioners), are refrigeration equipment built expressly to provide accurate temperature and humidity control in all applications requiring a high degree of precision. Precision air conditioners are utilised in data centres, where cooling loads can range from 5 to 20 kW, server rooms, data centres, mobile, and laboratory applications, as well as a variety of other industrial applications. Hidros precision air conditioners are designed and manufactured utilising components from renowned international manufacturers. They operate on environmentally benign refrigerants and offer a high degree of flexibility. Additionally, all items comply with the European directive ErP2015.

The classifications are based on the amount of chilly air discharged. The downward-flow unit exhausts cold air from the bottom and returns warm air from the top.

While the upflow unit exhausts cold air from the top, the return unit exhausts warm air from the front bottom.

If the room's ceiling height is less than six feet and there is no possibility of installing higher flooring, an upflow unit is preferred.

Downflow units are recommended for datacenters because cold air escapes through the perforated tiles of raised floors, resulting in frigid aisles.

Chillers vs. DX Units The primary distinction between these two types of units is that DX (direct expansion) units cool air while chiller units cool water. DX Units can be used as supplemental or emergency building air conditioning or as primary air conditioning at tented events or relief buildings. Chiller units chill water for use in various types of air conditioning systems, such as chilled water air handlers.

The DX Air Conditioner system cools air that enters through a supply plenum and returns it to the area that requires cooling via the return. The unit circulates refrigerant effectively through a sequence of condensers and evaporators, where heated air is cooled and sent through the return. Another significant characteristic of DX Packaged units is the ability to house the entire cooling system in a single unit. This enables them to be installed on top of or alongside a building without taking up an excessive amount of space, and they are often less expensive to install.

The DX unit is self-contained.

There is no risk associated with the DX unit.

Chiller units, like DX units, use a vapour expansion/compression cycle to cool liquid refrigerant. The refrigerant is changed continually from a liquid to a vapour and back. This procedure chills the refrigerant as it travels through an evaporator. Warm water is passed over the evaporator via a supply pipe with a radius of 2-5 inches and cooled to the required temperature. The cooled water is typically used to cool existing air handler systems.

Chilled water units required chilled water to be supplied by the central cooling plant. As a result, its cooling performance fluctuates according to the temperature of the entering cooling water. The temperature of the cooling water from the central plant is constantly changing.

The chilled water unit's operation is contingent upon the central cooling plant's uptime.

There is a potential of water leakage in a datacenter when using a chilled water unit.

However, chilled water units have a lower operating cost (electricity cost) than DX units.

High heat load or sensitive places such as data centres, computer rooms, sensitive storage facilities, medical facilities, etc., necessitate the use of close control units that have been meticulously engineered to meet their specific needs and requirements.

It is possible to measure the capacity of a close control unit in KW or tonnes. It is necessary to calculate the heat dissipation from all of the equipment installed within the Data centre in order to determine how much capacity is required. The server is the most significant source of heat generation. The specifications of servers and other equipment can be used to compute the quantity of heat generated by the equipment on a per hour basis.

To accomplish total heat dissipation, multiply the BTU/hr of all servers and other devices together and divide the result by 100. In addition, we must take into account the heat generated by the lights, the number of people working, the frequency with which doors are opened and closed, and the amount of time the datacenter walls are exposed to sunlight, among other aspects, when calculating the energy consumption.

Yes, using an SNMP card, also known as a pCOWEB card, we can monitor the device remotely. Through the use of an SNMP card, we may connect the Close control unit to the LAN/WAN network and assign it an IP address. We can view real-time data from a nearby control unit with the usage of an IP address. Dry contact units, which come standard, can also be utilised to connect the unit to a building management system (BMS).

The pCOWeb card must be added in order to connect the pCO Sistema to networks that use HVAC protocols based on the Ethernet physical standard, such as BACnet IP, Modbus TCP/IP, or SNMP.

BACnet is a building automation communication protocol based on American Society of Heating, Refrigerating, and Air Conditioning (ASHRAE) standards (American Society of Heating, Refrigerating and Air-Conditioning Engineers). As a result of these standards, which are available to manufacturers, BACnet devices can be built and made interoperable with one another in a variety of systems. The BACnet organisation maintains BTL laboratories (BACnet Testing Laboratories) to ensure that standards are being implemented correctly. The pCOWeb card has been evaluated successfully by BTL laboratories. Bacnet.org is a good starting point.

Modbus (modbus.org)is the most widely used HVAC/R protocol since it is reasonably easy to integrate into all development packages and consumes a little amount of the system's HW and SW resources. Modbus.org is a valuable resource.

SNMP (Simple Network Management Protocol) was developed by the Internet Architecture Board (IAB) as a protocol for IP networks in order to enable commands for exchanging data between various devices connected to a network. As a resource, snmplink.org is available:

Additionally, the card includes an integrated Web-Server that keeps the HTML pages associated with the particular programme and enables remote system control via a browser. Additionally, an internal logger is provided for the creation of logs (.CSV files) for twenty variables, as well as a graph for five variables based on the data from the logs (.SVG file). On a regular basis, these files will be sent via e-mail.

A remote connection over a network such as the Internet can be used to update the application running on the pCO.

It is possible to integrate software (plug-ins) written directly by users into the embedded LINUX operating system in order to meet their special requirements.

Along with the Supernode, pCOXs, pCO1, pCO3, pCO5 Compact, pCO5, and pCO5+, the pCOWeb card is compatible with the entire range of pCOSistema controllers with a BMS card slot: pCO1, pCO3, pCO5, and pCO5+.

Commercial facilities feature some of the most difficult HVAC implementation scenarios. Within each facility, a steady balance must be struck between equipment capability, automation, and a range of potentially unique requirements. Complicating matters further are rising regulations for cleaner and more efficient energy use, which may put established industry practises and processes under pressure.

There are numerous HVAC equipment manufacturers on the market today, and sourcing systems and components has never been easier. One of the most effective methods for determining the finest solutions for your specific requirements is to evaluate the offerings of industry leaders.

Leading Brands available in Market: Liebert, Airedale, BlueBox, Stulz, Emerson, APC, Uniflair, DENCO, Emicon,

Famous Models available in Market: Liebert DS, Liebert Mini-Mate2, Liebert CRV, Liebert CW, Liebert ICS, DENCO, Denco T-Range, trane, Denco TW-Range, Denco E-Range, Denco MS-Range, Uniflair AMICO, Uniflair LEONARDO EVOLUTION, Uniflair LEONARDO MAX, Uniflair MONOBLOCK, Blue Box DATATECH,